|

Do It Yourself

This

is my radon mitigation project of 2004.

I hope it servers as a learning tool that

can be improved upon. It may not be elegant, but "judge

only by results."

Caution

Radon mitigation is serious business.

It involves alterations to the structure of your home. Installation

of electrical circuits are best left to professionals. De-pressurization

of crawl spaces and slabs can cause negative pressure in living

spaces which may result in a backdraft condition for

gas

appliances, causing carbon monoxde gas to leak into the home.

Luckily, my house happened to have direct vent appliances, but

at the time I did the installation, I did not check for back

draft conditions. After taking the Residential Radon Measurement

and Mitigation Provider Courses, I realized the potential dangers

of not checking for back drafts. Please, only attempt a do-it-yourself

installation once you have read Doug Kladder's book (above)

and are prepared to make a safe installation.

Caveat

I

write this as a do-it-yourselfer to others who may want to do

it themselves, but I can only assume liability for my own installation.

You can use this information as part of your research, but I

cannot assume responsibility for how you put it use.

Testing

in

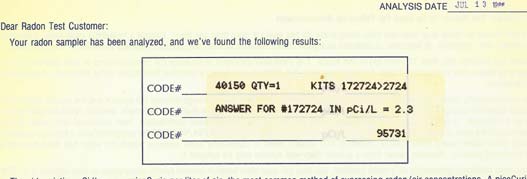

1988, after years of hearing about radon, I was somehow motivated

or curious enough to send for a test kit and test my house.

That summer I received in the mail a lab result that showed

my test had found levels of 2.3 pCi/L, below the 4 pCi/L action

level recommended by the EPA.

The literature recommended a follow-up test, but I became too

busy with "life" and the results were not "that

bad" so I put the project on the back shelf. I did buy

a book on radon, Radon, The Invisible Threat, by Michael Lafavore

(still available on Amazon under used books, see Connections),

which I never read, until just now. As the years went by I always

wanted to get back to that follow up test, but it never climbed

up the priority ladder on my list of things to do.

I

don't exactly know what got me going again, but in the winter

of 2003/2004 I finally took the time to search on the Internet

and found a new radon testing device called the Safety Siren

Pro Series II Radon Detector. I wanted a unit I had more control

over than a one-time charcoal test and this little unit looked

portable, re-useable and the catalog recommended it, so I took

a leap of faith and purchased the tester. I

don't exactly know what got me going again, but in the winter

of 2003/2004 I finally took the time to search on the Internet

and found a new radon testing device called the Safety Siren

Pro Series II Radon Detector. I wanted a unit I had more control

over than a one-time charcoal test and this little unit looked

portable, re-useable and the catalog recommended it, so I took

a leap of faith and purchased the tester.

When

the unit arrived, I plugged it in and within days noticed readings

of 2 - 3 pCi/L. This was in the spring of 2004. By Summer and

Fall the readings were up to 3 - 4 with the annoying alarm going

off at 4 so it encouraged me to go to the next step, which was

to buy tarps to cover the crawl space (see below). By winter

I was getting readings of 5 - 6 pCi/L.

Plans

I

searched on the Internet for plans and found a company called

Infiltec which has diagrams

of about every mitigation installation you can imagine. I printed

out the ones that seemed to match my house construction and

then talked to a few radon supply companies to confirm that

I was designing according to current specifications. The design

I was following showed a plastic barrier on the ground in the

crawl space attached to the stem walls, with a perforated pipe

under the plastic, running down the full length of the crawl

space. The perforated pipe was then attached to a PVC pipe that

curved up and out a hole in the stem wall and attached to a

fan that vented it up through the roof overhang.

The

Design

The

idea was to use a low volume fan to create a small negative

pressure in the perforated pipe under the tarp. Then whatever

radon gas in the soil that was migrating up into the crawl space

and then into my house, would be drawn toward the slight negative

pressure in the pipe and be exhausted up the flue on the side

of the house, through the eve of the roof and be dissipated

in the air above the roof. This method does not actively vent

the crawl space because the radon is removed from under the

tarp before it has a chance to get to the crawl space. This

assumes that there are no leaks in the tarp and the duct tape

will seal the tarp edges forever, which is probably not the

case with my installation. More on that later.

Crawl

Space Plan

from Infiltec

Slab

Foundation Plan

I

have not installed the slab foundation plan, but I am told that

home owners with this foundations can do the job relatively

easily and cheaply, compared to the crawl space system I attempted.

According to some folks I spoke to, you need to jack hammer

out an 18 inch round hole in the slab and dig down about 6 to

10 inches. Then you insert a 4 inch PVC "T" into the

hole and attach a 4" vent pipe to the end of the"T"

sticking up into the room. You then cover the open ends of the

"T" with breathable drain cloth to keep the dirt out

of the pipe, cover the entire "T" up with gravel so

it will take the weight of the cement, and then fill in the

hole with cement. I was told that this can be done in a closet

and the vent pipe run up to the attic where the fan is installed

and the vent pipe rises through the roof. The negative pressure

in the "T" will cause the radon under the entire slab

to migrate to the pipe and be vented out. Sounds amazingly simple

without having to purchase or install tarps and drain pipes,

which was a pretty big job.

(Note:

This is a general, uneducated, hearsay description, not intended

as a plan. If you plan to install this type of system, get some

good installation books (see Doug Kladder's book above) or hire

a professional mitigator).

The

Crawl Space

A

friend of mine had just used some heavy duty poly tarps to replace

the torn plastic vapor barrier in his crawl space. His goal

was not radon control, he just wanted a good vapor barrier and

to make his crawl space cleaner when he had to crawl under the

house to tack up insulation or run stereo wires or whatever.

I thought that silver tarp would also do the trick for a radon

barrier (though now, if I had it to do over, I have found some

rolls of nylon-reinforced 6 mil plastic sheeting that would

have made less seams to seal. Also there is a spray adhesive

that is a better method for sealing seams than the duct tape

that I used. See the product list at the end of this page).

So I made the trip to Carson City Home Depot and bought 3"

perforated drain pipe (used for French drains), 3" connectors

and 90's, double-thick silver and brown poly tarps, and plenty

of good quality duct tape. Truthfully, it took me two additional

trips to Home Depot to get enough tarps and duct tape to cover

the entire 1000 s.f. crawl space. At the end of the three trips

I had spent $232.39 on supplies.

Note: The picture at right shows the tarp being staples to the sill plate. This is NOT a recommended installation! The radon barrier cloth should be glued to the concrete foundation wall well below the sill plate. Moisture can rot out the sill plate and termites can get into the house behind the tarp. This installation is being fixed. Use the correct adhesive the first time, not like me!!

The

Perforated Pipe

To lay the drain pipe I simply attached the 4 10' sections of

rigid drain pipe together with the connectors and laid the 40'

down the center of the crawl space. I had to cut off about 4

feet with a hack saw to make it fit. I then used a 90 to bend

the pipe up toward the floor over head. At this point I adapted

the 3" pipe down to a 2 1/4 PVC pipe to fit through a 2

1/4 hole I already had drilled in the stem wall. I used good

old duct tape to make it all fit. (Later I undid this setup

and used 4" ABS to go through an existing air vent in the

stem wall).

The

Tarp

To lay out the tarp I needed the help of someone who wouldn't

mind spending hours working in a cramped, dusty and dirty crawl

space. Luckily my neighbor's son, Justin, had proved he was

not afraid of hard work when he helped me with a difficult landscaping

job that summer and he was willing to pull on the coveralls.

I insisted on paying hazard pay. We donned coveralls, dust masks,

gloves, hats, and grabbed tape measurers, flash lights, extension

lights, duct tape, staplers, scissors and climbed in. We laid

out the first tarp by the door and taped and stapled it to the

stem walls. We allowed it to drape down to the dirt floor and

run across the floor to the concrete and wood posts lining the

center of the crawl space.

We

took some scrap tarp squares maybe 3 feet on a side and cut

them from a corner down to the center. We wrapped the squares

around the posts so the concrete base was covered and the upper

wood post was covered and we used duct tape to secure the square

to the post. Then when we pulled the tarp across the floor to

where the first post was, we cut the tarp and laid it around

the base of the post which was already wrapped with the tarp

square. Thus when we taped the tarp to the post we were really

taping the tarp to the cut square so our tape was able to get

a good grip and eliminate air pockets. We

took some scrap tarp squares maybe 3 feet on a side and cut

them from a corner down to the center. We wrapped the squares

around the posts so the concrete base was covered and the upper

wood post was covered and we used duct tape to secure the square

to the post. Then when we pulled the tarp across the floor to

where the first post was, we cut the tarp and laid it around

the base of the post which was already wrapped with the tarp

square. Thus when we taped the tarp to the post we were really

taping the tarp to the cut square so our tape was able to get

a good grip and eliminate air pockets.

We

worked around the crawl space starting at the stem walls and

working our way to the center, dealing with each post as we

had the first. We used plenty of duct tape to seal all the overlapping

tarp edges where two tarps joined. In the center of the crawl

space where the perforated pipe lay, we simply laid the tarp

over the pipe without taping it, and continued to the next tarp.

The job was difficult crawling under the house to lay and tape

the tarps. It took two of us 6 hours one day and 7 hours the

next, for a total of 13 hours under the house. So, with hazard

pay, my helper's labor bill came to $206, or $15.85 an hour

average: twice the bargain at any price - Thanks Justin!

Note:

The tarp in the above photo should be glued to the concrete

pier, not to the wood! This installation has been fixed, see

photos at bottom of page.

The

Fan

After some searching, I happened on an Internet source for radon

supplies with the unlikely name of radon

supplies.com. They had a catalog with good photos and helpful

people who,though they disclaim being designers, gave me confidence

that my design should work. I described my system and said that

I wanted a fan with very low air volume because I was not moving

air, but rather creating a negative pressure under the tarp.

The radon gas in the soil would then migrate toward the negative

pressure in the perforated drain pipe and be drawn up the flue

along side my outside wall to the outlet on the roof.

We

picked out a Fantech fan that we thought would meet my low pressure,

low volume needs. We choose the Fantech

HP series # HP2133. It a low 14 to 20 watt rating and a

low .17 max amps. I thought this fan should be cheap to run

and quiet. It is both. I think it should last a long time as

well, though that's to be seen. From the folks I have spoken

to, these fans last about 7 to 8 years of continuous operation,

if condensation problems are eliminated (see below). Cost: $133.

The

Drain Pipe

Warm air from under the house contains a fair amount of moisture

which will condense out in the uninsullated pipe in the winter.

I found a company, when I took the Radon Mitigation Certification

Course in Colorado Springs, that has developed a special drain

pipe that allows moisture to drain out in the winter. It is

located right above the fan. You can see the small drain holes

above the white coupling. I am able to supply these special

drain pipes to anyone installing a system in the Tahoe area.

Call for prices. After taking the classes on testing and mitigation,

I discarded my original insulated pipd and changed regular 4

inch metal drain pipe which matches the color of my house and

looks just like a normal drain pipe.

The

couplings and adapters

Originally I made the mistake of adapting my 3" perforated

pipe down to 2" PVC to get through an existing hole in

my stem wall and then adapting the 2" PVC back up to the

4" opening in the fan. Bad design. Too many changes in

size to allow the fan to create enough negative pressure to

extract the radon from the soil, and costly to purchase all

those adapters. So I decided to replace the adapters with 4"

ABS all the way from the 3" perforated pipe to the 4"

opening in the fan.. I purchased "sweep 90" ABS connectors

to make the 90 degree bend more gradual and less restrictive

on the air flow. After this picture was taken I took

off the duct tape and used ABS glue to seal the joints.

Note:

See picture below and additional pics at the bottom of this

page for re-make of this installation.

The

Air Vent

I now needed to get through to the outside of the house. I asked

a friend if I could borrow a hole saw to expand my 2 1/2 inch

hole in my stem wall and he said: "Why mess with the hole?

Just take the pipe through one of the air vents" Well....ok!

There happened to be an air vent very near the 2 1/2" hole.

I removed the louvered air vent screen (about 7" x 13")

and replaced it with a simple, non-louvered air vent screen.

I cut a 4" hole in the screen material and shoved the 4"

ABS through it and screwed the screen back in place. Done, finished,

and no hassle trying to drill a 4' hole in a 2x12 stem wall.

Thanks, Oly!

The

Electricity The

Electricity

Fans need electricity and outside fans need outside electricity.

Once again I was in luck to have an outside electrical outlet

already installed about 7 feet from the fan. The fan came with

no cord, so I used # 12 solid wire in outdoor conduit, hot,

neutral and ground, with an weather-proof on-off switch just

incase I needed to turn off the fan in an emergency. I used

outdoor flex conduit between the switch and the fan.

The

Vent Pipe

Though I used an insullated pipe system when I first installed

my radon mitigation system, I leaned that the use of simple

metal rain gutter downspout pipe works the best. I obtained

the downspout from a company in Colorado with the special fittings

that attach it to the round 4 inch PVC 45 degree couplings.

Very simple and natural looking. At least brown downspout looks

better than large white round pipe going up the side of the

house.

The

Top Vent

Venting radon up and out does not send it over to the neighbors

but just disperses it into the air. Remember, it is the concentration

of radon gas in a closed environment that is the problem. The

best way to get the gas to disperse is to vent it up to the

top of the roof with no top cap to restrict the flow. the forceful

flow of air keeps most rain and snow out. If rain or snow does

get in, it will drain out the bottom drain holes above the motor.

At least that's what the book says. This winter will tell the

real story! More pictures in the spring.

The

Results

It took about a week to see the radon numbers change on my digital

LED display. That was because I had not quite understood what

the two modes on the Series II radon detector meant. I had it

set to "long term" and it was reading 5. At the end

of the week I tried it to "short term" and it immediately

registered 1. I later learned (when all else fails, read the

manual) that the detector senses radon each hour and it averages

those hourly readings over 7 days for short term and over how

ever long the unit had been plugged in for long term. Short

term would have been the correct setting to see the changes

immediately, but by 7 days I was getting 1 pCi/L and no annoying

alarm, so I was happy. And my family is safer. It has read 1

for the last month with only 3 days of a 2.

The

Costs

The

costs below are for my initial design using insulated vent pipe.

The 4 inch rectangular metal rain gutter with PVC adapters and

drain pipe and shipping added to the costs for me but would

be about the same as the chart below for someone keeping with

one design.

| Pro

Series II Radon Detector |

Safe

Home Products |

$99.45

|

|

Heavy

Duty Poly Tarps

to cover 1000 s.f. crawl space

|

Home

Depot |

$191.67

|

| Duct

tape - 3M |

Home

Depot |

$23.89

|

| Perforated

drain pipe 3" X 10' |

Home

Depot |

$13.88

|

| Fantech

HP2133 low volumn radon fan |

Radon

Supplies |

$133.38

|

| Polar

Pipe 25' 4" pipe |

Radon

Supplies |

$150.00

|

| Polar

Pipe insulated exhaust cap |

Radon

Supplies |

$32.10

|

| Pipe

coupling adapter 4" to 3" |

Radon

Supplies |

$12.75

|

| Pipe

coupling adapter 4" to 4" |

Radon

Supplies |

$12.75

|

| EZ

Snap Clamps 4" to anchor pipe to building |

Radon

Supplies |

$23.20

|

| Freight |

Radon

Supplies |

$69.94

|

| ABS

4" pipe, 90's and couplings |

Meeks

Lumber |

$52.26

|

| |

|

|

| |

|

|

| Total

Material |

|

$815.77

|

|

|

|

|

Labor

2 days at 6hrs, 7hrs, @ $12 / hr

+

$50 "hazard pay" mostly cutting, laying and

taping the tarp under house

|

for

helper, not counting my time |

$206.00

|

|

|

|

|

| Total

Costs |

|

$1021.77

|

Looking

Back

I installed this system in the Winter of 2004. In the Spring

of 2005 I took the Residental Radon Measurement Provider Course

and the Residential Radon Mitigation Provider Course from Douglas

Kladder's CERTI - Center for Environmental Research and Technology,

Inc., in Colorado Springs, Colorado. While much of my do-it-yourself

design worked to lower my radon readings, there are certain

things that I would do differently. I would not use plastic

tarps from Home Depot, but would use special rolls of ground

cloth and special adhesive to make better seals than duct tape

could ever do. I may eventually re-do the crawl space if radon

levels ever rise above 1. But for now I am living with it as

it is and the reduction in radon from 5 to 1 is an indication

that even a less than perfect job produces good results.

Many

supply companies sell a 6 mil. crawl space barrier that comes

in 20' x 100' rolls that would have meant less seams to seal.

There are various adhesive that seal the edges of the plastic

sheeting so I would not have had to use any duct tape, or at

least not much. Cost wise, the tarps cost me $191 at Home Depot

while a roll of crawl space barrier would have cost me $150

plus about $15 in shipping. The duct tape cost me $24 while

the spray would have been $10. The savings would have been around

$40, and it would have been easier to install, so I would have

saved some on labor (plus the wear and tear on me!) but the

big reward would have been a more gas resistant, air tight finished

product. Many

supply companies sell a 6 mil. crawl space barrier that comes

in 20' x 100' rolls that would have meant less seams to seal.

There are various adhesive that seal the edges of the plastic

sheeting so I would not have had to use any duct tape, or at

least not much. Cost wise, the tarps cost me $191 at Home Depot

while a roll of crawl space barrier would have cost me $150

plus about $15 in shipping. The duct tape cost me $24 while

the spray would have been $10. The savings would have been around

$40, and it would have been easier to install, so I would have

saved some on labor (plus the wear and tear on me!) but the

big reward would have been a more gas resistant, air tight finished

product.

I

also would have gone straight for the air vent to get the 4"

ABS pipe to the outside, without spending time and money on

adapters to try and size the 3" drain pipe down to a 2"

hole and back up to a 4" pipe at the fan.

As

in all projects, you may want to check on the price of having

the work done professionally before you decide to do the job

yourself, if you can find anyone. In my case, I just thought

I could do it myself, so I jumped in without checking on professional

help. As it turned out it was not too difficult and it did the

trick of lowering the radon levels, which was the goal. Hopefully

you can learn from my mistakes and my research, so you will

likely get a better job at cheaper price. But, if you do hire

it out, check references, certifications, and licenses and beware

of house repair rip-offs. Good Luck!

Deadly

Back Drafts

After taking the Residential Radon Measurement Provider Course

and the Residential Radon Mitigation Provider Course, I have

discovered many ways to improve this installation. The most

important safety issue is to test for back drafts from gas appliances

when de-pressurizing a crawl space or foundation slab.

Carbon monoxide poisoning is a deadly mistake you don't want

to make. Learn how to test for it or hire a professional.

Reasons For NOT Installing the Radon Fan in the Living Space

I am often asked by homeowners if it is ok to install a radon fan in the crawl space or in a closet to accomodate an easy installation. Several members of the Radon Professional List Serv sounded off (in February, 2010) on the question of why not to install a radon fan in the living space. I incorporated that discussion into one document as a resource when this question comes up again. This is not the end to the discussion, of course, but these radon professionals make some compelling arguments for sticking with EPA protocols.

The consensus is to follow EPA guidelines and keep the radon fan outside or above the living space, as in the attic. But not to put it in the basement, crawl-space or interior closet.

Read the reasons

2010

Make-Over

It took a few years to want to go back in and re-do the crawl

space, especially since the radon readings were (and are) still

in the 1's, but I finally decided to hire it out to get it done

right. I hired a certified radon contractor to replace plastic

tarps with the correct radon barrier cloth (we actually just

left the tarps under the barrier cloth) using the correct polyurathane

adhesive and also removing any contact with wood (to avoid the

chance that termites might be active in any wood out of sight

under the barrier cloth. Here are the current (as of 3-28-12)

pictures of the finished and hopefully in spec crawl space.

It is interesting to note that correcting the original tarp

job has not altered or improved the functioning of the system.

It still remains at between .07 and 2.0 pCi/L.

|